Let's take a step back to when you had the "aha moment". You identified a problem and were excited about creating a consumer product that customers resonated with and wanted to buy. Most importantly, you were not relying purely on your intuition or sixth sense, but on the results of extensive user research that provided you enough initial insights into your target market and the problem itself.

“They slow us down to speed us up. By taking the time to prototype our ideas, we avoid costly mistakes such as becoming too complex too early and sticking with a weak idea for too long.”

-- Tim Brown, CEO, IDEO

Based on the user research, you developed a works-like prototype, i.e. a working model which demonstrates the intended functionality. You should iterate your works-like prototype with users and evaluate the product's technical and functional viability.

You can use this proof-of-concept to demonstrate the performance and functionality of your product to investors to gauge their interest.

Entrepreneurs who involve their stakeholders, esp. their customers during product development have a greater probability of success.

At this stage, you should also have a Product Requirements Document (PRD) that articulates your product’s features, purpose, functionality and technical requirements. It includes everything that is needed to build the product - such as electronics (PCB, processors etc), BOM components, mechanical components, materials and enclosures, firmware, packaging and compliance and regulatory requirements.

This is an evolving document and an important aspect of the planning phase that will be referred to at the later stages of product development too. Startups must invest enough time to develop an effective PRD.

The Design Intent

The full user experience and design comes after the technical feasibility has been ascertained. At this stage, you create a looks-like prototype that looks like the final product but doesn't necessarily function.

The objective of a looks-like prototype is to help you test assumptions of product design and its interaction with the users. As you iterate and come up with improved versions, you should be able to discover the 'must-have' and 'nice-to-have' features too.

An industrial designer usually starts with several product sketches to select a few concepts and then conducts a form study using crude prototypes to test the product’s ergonomics and proportions.

Does the product 'feel right'? Should that button be placed at the top? What should you do for a better user experience? How should the packaging be designed?

Those are the kind of questions that need to be answered at this stage.

Testing Early Prototypes

Testing is the most crucial part of the product development process and can prove costly if not done properly. It is also one of the reasons why hardware startups fail. You should use each iteration as an opportunity to test your prototypes to maximize the value you derive from them.

Also, as much as possible, you should try to test individual components/sub-assemblies first instead of the whole product. You should test your early stage prototypes for:

Usability; to refine and enhance the industrial design and user experience. You should test early and often and aim to get feedback on form as well as functionality of the product.

Materials and finish; to assess different materials for durability. You should test materials, paints and product finish for degradation, discoloration and even allergies etc to ensure a good quality product.

Critical components; to ensure that the critical components of the product are robust. These should be analyzed as separate parts under varied, sometimes imperfect conditions that are as close as possible to real life.

Design meets Engineering

You now have two prototypes: one works and the other looks great. The works-like and looks-like prototypes need to be merged into one to come up with a fully functional prototype.

This isn’t as easy at it may sound and may need modifications and compromises on both the engineering and design side.

DFM and DFA

You have a near-production version of the product. Should you now start manufacturing at scale? Not yet! Your final prototype isn't designed for manufacturing (DFM). You need to take into consideration the points listed below along with the fabrication, processing and assembly.

Your final prototype may be using parts that are inexpensive in order to create a few prototypes (e..g 3D printed parts or Arduino boards), but not cost-effective for mass production.

The PCBs in your product (if applicable), should be first optimised for performance, cost and reliability.

The metal and plastic components and casings need to be optimised as part of DFM in order for manufacturing in large volumes while maintaining consistency and durability/strength.

Just like DFM, planning for DFA (Design for Assembly) early on during product development can significantly affect cost, quality and timelines. You should design products such that they can be assembled from beginning to end efficiently and cost-effectively.

Can you minimize the parts count? Ensure that your Product requirements document keeps changing as needed.

The overall design should be done keeping assembly in mind and should be done to ease it. Think about ways to reduce complexities during assembly and disassembly.

How will parts be stacked up and transferred on the assembly line?

What can be avoided? Screws, adhesives, sharp parts,

Can the parts be standardised? Can you use modular designs?

Avoid parts so small that they can’t be grasped or manipulated easily.

Can each part can be assembled by technicians who are not engineers?

Fundraising and Sales

Using the near-production version of the product, you can begin your fundraise. This is the closest you have got to the actual product and is the largest step in the whole product development process. This production ready product should be good for investors to understand the product.

If you have enterprises/businesses as your customers, you will know that it could take several weeks to close sales. Therefore, you must initiate those customer conversations and demo your product given the time frame available to deliver the production version.

The Supply Chain

An important part of the overall product development that startups often struggle with is the supply chain management (SCM). It is important to have an effective supply chain, distribution and logistics strategy to avoid incurring costs and customer delays.

Critical information and communication can get lost if a company doesn’t have a one-point contact to manage the supply chain. It can be the founder, an internal resource or a contractor.

Know your BOM (Bill of Materials) down to the last component. You should know where the parts are coming from, who your suppliers are and plan ahead in time to be able to save on costs.

Don’t rush to select a manufacturing partner. Will manufacturer be able to optimise and design for manufacturability? The DFM analysis must be tied into the diligence that you will conduct on potential manufacturers.

Design for Logistics. Design products such that they are easy to ship, shelf and (re)pack. Standardise processes, parts and procurement. Optimize packaging. Think parallelization of assembly and logistics.

Figure out your warehousing and shipping strategy and conduct thorough diligence if employing a third party.

If you are manufacturing in a foreign country, you must be aware of everything that is needed in order for the manufacturing to happen and then the shipment to move into your home country and get distributed/retailed.

Plan ahead in time to save shipping costs. For e.g. it can take a few weeks for a shipment to arrive from China to the US via ocean freight. Does that mean you ship by Air and spend several times over? Not necessarily. You can just plan the shipping time into your overall timelines to avoid delays.

Testing

It is now time to test the pre-production prototype as you prepare for mass production. The test strategy at this stage encompasses Engineering Validation Test (EVT), Design Verification Test (DVT) and Product Validation Test (PVT).

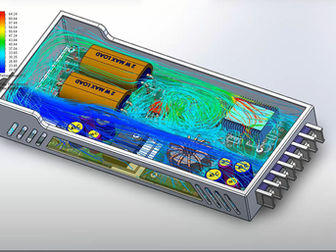

EVT is done with the objective of ensuring that all functional requirements of the product specification have been met and the system performs as per design goals. Now is the time to pull out your product requirements document and ensure that all functional requirements have been met. Tests as part of EVT may include:-

Mechanical fit test

Functional tests

Usability at the system level

Thermal test

Power consumption, Signal quality and Conformance

EMC scans

Another EVT build is performed if major design flaws are identified.

DVT is done to test all the possible product requirements including functional, interface standards, environmental, mechanical and cosmetic. This is usually carried out in the same factory where the product will be (mass) manufactured. DVT units are put through a lot of rigorous tests including:-

Mechanical (tumble, 6 face drop, vibration etc)

Functional and usability testing

Accelerated Stress test

Performance

Climatic

MTBF prediction

Regulatory and compliance

PVT is the final stage in the pre-production testing. This is where the manufacturing process is tested. It is the first official production run, with typically 500 or more units, to determine if a quality product can be built up fast enough and at scale while maintaining quality. This is the reason why the PVT build should be as close as possible to the mass production workflow and no changes to the product are allowed at this time (unless very critical of course). This is the final chance for any tweaks (fixtures, tools or processes) before the PVT units go through thorough quality checks to ensure a reliable assembly. If all goes well, you can ship these units off to customers!

Manufacturing

This the first full production run. As the units get manufactured, one must start thinking about bringing in supply chain efficiency and build tools that help predict demand and volumes.

"Manufacturing is more than just putting parts together. It's coming up with ideas, testing principles and perfecting the engineering, as well as final assembly."

-- James Dyson

Consider enough diligence on your manufacturer to make sure they will be able to handle the volumes you are expecting.

Always consider your manufacturer as your partner and maintain a good relationship.

Continue to spend time at their factory and be aware of any process changes at the factory level that may affect you.

Shipping

Now is the time when it really comes together! Here are the key considerations when you are shipping your products.

Determine how you are going to ship your products and find partners to make it happen.

You will need a freight forwarder if shipping internationally.

Besides the cost of shipping itself, you need to consider packaging, shipment tracking and warehousing costs. Depending on the destination and mode of shipping, you need to consider the taxes and duties that will be incurred.

Are you going to charge the customer for shipping or absorb that cost into the product price itself or offer free shipping?

You need to decide how you’d like to position yourself. It is a balancing act between delivery lead times and the overall costs.

There is no better feeling than to see your customers actually use your product. Now should be the time for you to ensure excellent customer service as you plan your next batch of products delivery.

Comments